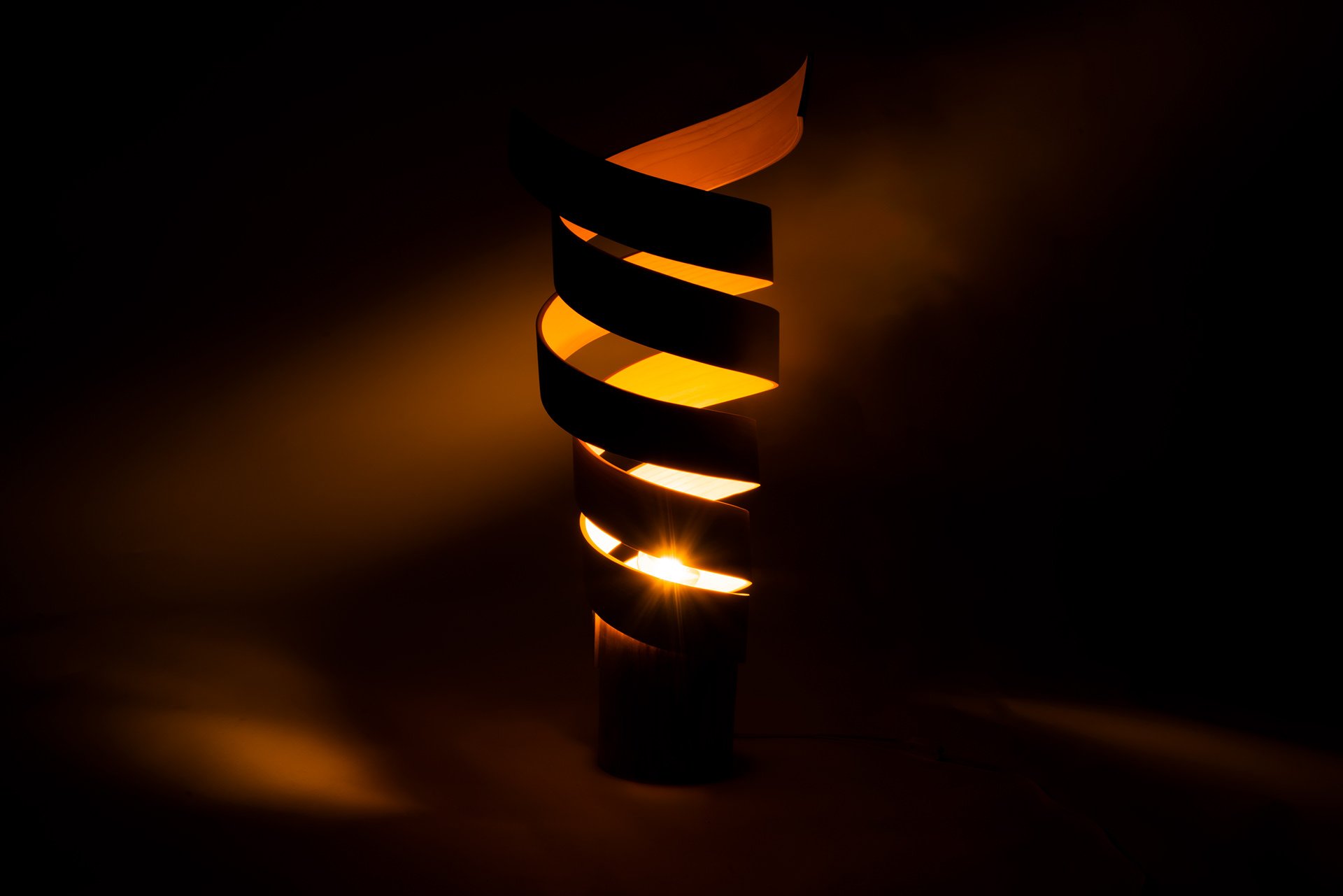

Spiralis Occasum

Spiralis Occasum is a floor lamp made out of solid teak and oak veneers. This piece is inspired by the sculptural pieces of Joseph Walsh, conveying fluidity and natural expression through the morphed wood.

Context

Undergraduate Project · Group

Team: E. Aldana, C. Hernández

Tools

Woodworking lathe · Illustrator · Photoshop

Timeline

October - December 2018

My Role

Product Designer

Joseph Walsh

State of Art

“Walsh’s work reflects his passion for expression through material and form. From monumental scale sculptures to one-of-a-kind site-specific commissions and collectible design editions, every piece within his dynamic body of work reveals an intuitive relationship with making, a sympathetic use of materials, and an expressive engagement with form”

Sketches: Ideation

Looking to create a floor lamp, we started with a rough volumetric sketch to capture the shape that we were trying to achieve from different perspectives. Also, we started considering the measurements and materials for the desired finish.

Initially, the height of the lamp was set at 1.80 meters, but in the process of creating a mold to shape the veneers we encountered an issue with its size, as a 2-meter mold would be heavy and challenging to work on, modifying it to 1 meter.

Woodturning

Process

To build the base of the lamp, I started by shaping the teak into a cylinder. This piece was modified with a lathe and chisels. Once we achieved the desired size, the leftover pieces on the sides were removed. To add the bulb, I used a standing drill press to create a measured space for the socket and a smaller hole for the electric system right in the center of the cylinder. Finally, the base was sanded and finished with beeswax polish to highlight the beautiful wood grain.

Process

Molding

For the rest of the structure, we began by gluing and stacking a series of 1.2mm oak veneers using a roller for uniform coverage and Carpincol 2500. To achieve the spiraled shape, the glued veneers were placed around the mold and secured using latex strips, pins, and clamps, holding the layered veneers together. The structure was left to dry for five days, repeating the same process for the second piece.

Once dry, the two structures were sanded, polishing the edges, and cutting the ends where the veneers were not fully overlapping. We finished the oak with beeswax as well. The two pieces were intertwined and secured to the base using screws and covered with wood putty.

Final Product

The name designated for this piece comes from two Latin words: spiralis, which means twist or spiral, and occasum which refers to the sunset.

Spiralis Occasum seeks to capture the expression of nature magnified by the light peeking through the spiraled structure, emulating the magnificence of the sunset. Seen from above, the lamp replicates an organic symmetry, reinforcing the idea of fluidity captured in the ascending grain of the veneers.